Tube Laser Cutting Systems Diy

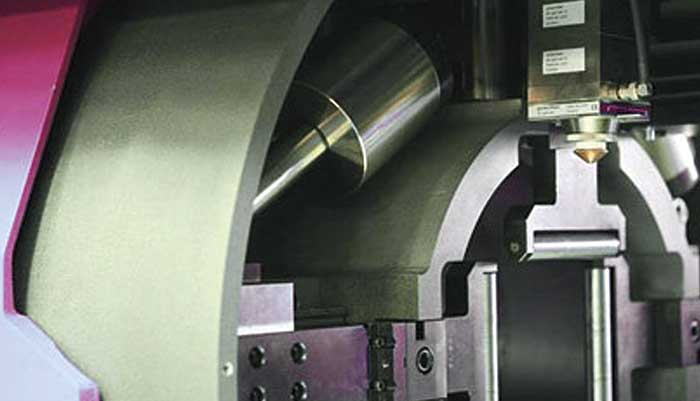

The most productive solution to tubes of any section. Tubes upto O 6" (152.4mm).2D cutCO2 (or fiber laser).

Find laser systems for electronics production that can perform high-precision, fast cutting, welding, marking and ablation of metals or plastics.